Talk:O2k-Chambers

From Bioblast

Revision as of 17:33, 19 March 2020 by Gnaiger Erich (talk | contribs)

Leaky Chamber

Leaky chamber test

- When the leakage is so little that cannot be noticed in a short amount of time, we recommend to follow the Leaky chamber test below:

- Decrease the oxygen concentration down to ~ 50 μM (using Dithionite or N2 injection)

- Let the O2k record overnight with the chamber closed and illumination switched off

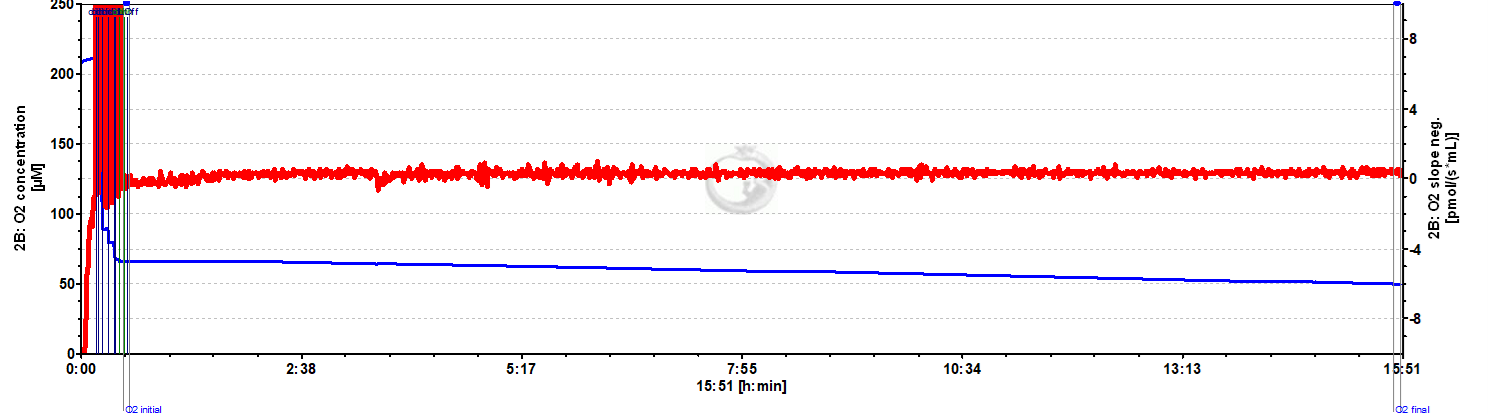

- The oxygen concentration should decrease overtime due to the O2 consumed by OroboPOS as it is shown in the figure. In this case, the chamber is assembled properly.

- If the oxygen concentration increases over time, a reassemble of the chamber is needed.

- Text in discussion for the page:

- To exclude the existence of an unnoticed leak from the chamber, we recommend performing the following Leaky chamber test - especially after chamber reassembly:

- Decrease the oxygen concentration down to ~ 50 μM (using Dithionite or N2 injection).

- Record the O2k measurement overnight with the chamber closed and illumination switched off.

- The oxygen concentration should decrease overtime due to the O2 consumed by the OroboPOS as shown in the figure below.

- If the oxygen concentration increases over time, a reassemblye of the chamber is needed.

- CecattoC (talk) 15:52, 19 March 2020 (CET). So, it should be done every reassemble otherwise nobody will noticed that? How frequent you received cases with this or noticed leaky chamber in our lab? If the user can see the decrease of oxygen consumed by the sensor in an half and hour or an hour closed chamber run, they don't need to perform the leaky chamber test, right?

Raising more questions in the end

Comments by Cristiane

- The instructions are very clear for me, the problem is when to do the test. I think people can think on skip this to avoid extra work (if they can’t see there is a problem). We can see that people still are not even doing instrumental backgrounds (in my previous lab it took us sometime to do it).

- I’ve been looking the pages in bioblast and I really like the Oxygen sensor test https://wiki.oroboros.at/index.php/Oxygen_sensor_test with clear points of quality control and what to do if they are not achieved.

- Don’t you think we can include quickly in this page (https://wiki.oroboros.at/index.php/Oxygen_flux_-_instrumental_background) the window of calibrating background and the range of acceptable numbers?

- And then include a sentence in both pages, for example: if your oxygen concentration is increasing or isn’t decreasing in a closed chamber without sample, you should perform a leaky chamber test (and a link for a test). What do you think about an alert: Do you know that POS consume oxygen itself?

- I would never think on do a test to see if there is oxygen leaking if I am not seeing something weird.

- I really don’t know what is best. Some users do everything correct, another can think that one more step for calibration is annoying. Some can’t maybe even see that this is a problem.

- We perform leaky chamber test in our O2k every assemble?

- In resume: I do not think that people will follow in a regularly basis, not a overnight run, at least. But maybe they can see a problem during a prolonged air calibration after POS-service (then we should advice to run some more time with closed chamber) and then this need to be written somewhere and need to be easy to find (for example, not everyone will look for “leaky chamber”.

- At the end I just raised more questions, than solving the previous one.

A story about gas bubbles appearing in the closed chamber

Gnaiger Erich (talk) 16:27, 19 March 2020 (CET)

- You are an O2k user who assembles the O2k-Chamber carefully following the SOP (manual & video). Usually this works very well - but not always ..

- You are stressed because you have a persistent problem with a leak after chamber assembly, loosing medium from the chamber (observed by medium dropping out from the OroboPOS holder and connector; or a gas bubble appearing slowly in the closed chamber).

- ‘Leaky chamber’, therefore, has to be defined: Here it is not just the oxygen leak (as observed in an instrumental O2-background test), it is actual medium leak – two entirely different processes, although medium leak causes simultaneously an O2 leak, but not the other way around.

- You re-assemble again and again, until the chamber appears to be tight. You have no clue, what you did differently. And you are not 100 % sure, if the chamber is now really tight. (This is meant by “When the leakage is so little that cannot be noticed”).

- You could test this easily with an instrumental O2-background test - SOP! You can do this even in a short amount of time, if you have other tasks to complete meanwhile. But unfortunately it is already evening, and the lab will be closed. (This is meant by “in a short amount of time”). Well, then you may quickly reduce the oxygen level .. the overnight ‘leaky chamber test’ (we will find a better title).

- You may use dithionite quickly. But probably you performed your tests of loosing medium after chamber assembly with H2O, to avoid any sticky medium clogging your sensor connector when medium leaks from the chamber. Do you now titrate dithionite solution into the closed chamber containing H2O? YOU WOULD BE IN TROUBLE! This is well explained in our SOPs, but it is a good idea to clarify, that you should use MiR05 (or a highly concentrated phosphate buffer). (Marco: did you actually use MiR05 – I guess absolutely YES).

- You come back to the lab in the morning – BINGO. The chamber is tight. Does this replace the instrumental O2-background test?